TOLL PROCESSING & SERVICES

STEEL & ALUMINUM FLAT ROLL

PRECISION COIL SLITTING

Our Braner Slitter Line is a 70,000# x 72” x 1,000 FPM Automotive Class-1 Double-loop Coated Coil with Inline Surface Inspection Stand, ranging in gauges from 0.013” to 0.250”, with Turret Head Design. This is Braner’s most technologically current line, improving upon those used by the nation’s finest automotive industry steel service centers. It is specially designed for surface-critical coated materials. With the Hi Pass line, large 88” entry O.D., and 72” width capability, this Braner line is one of the most universal and modern lines currently available on the West Coast.

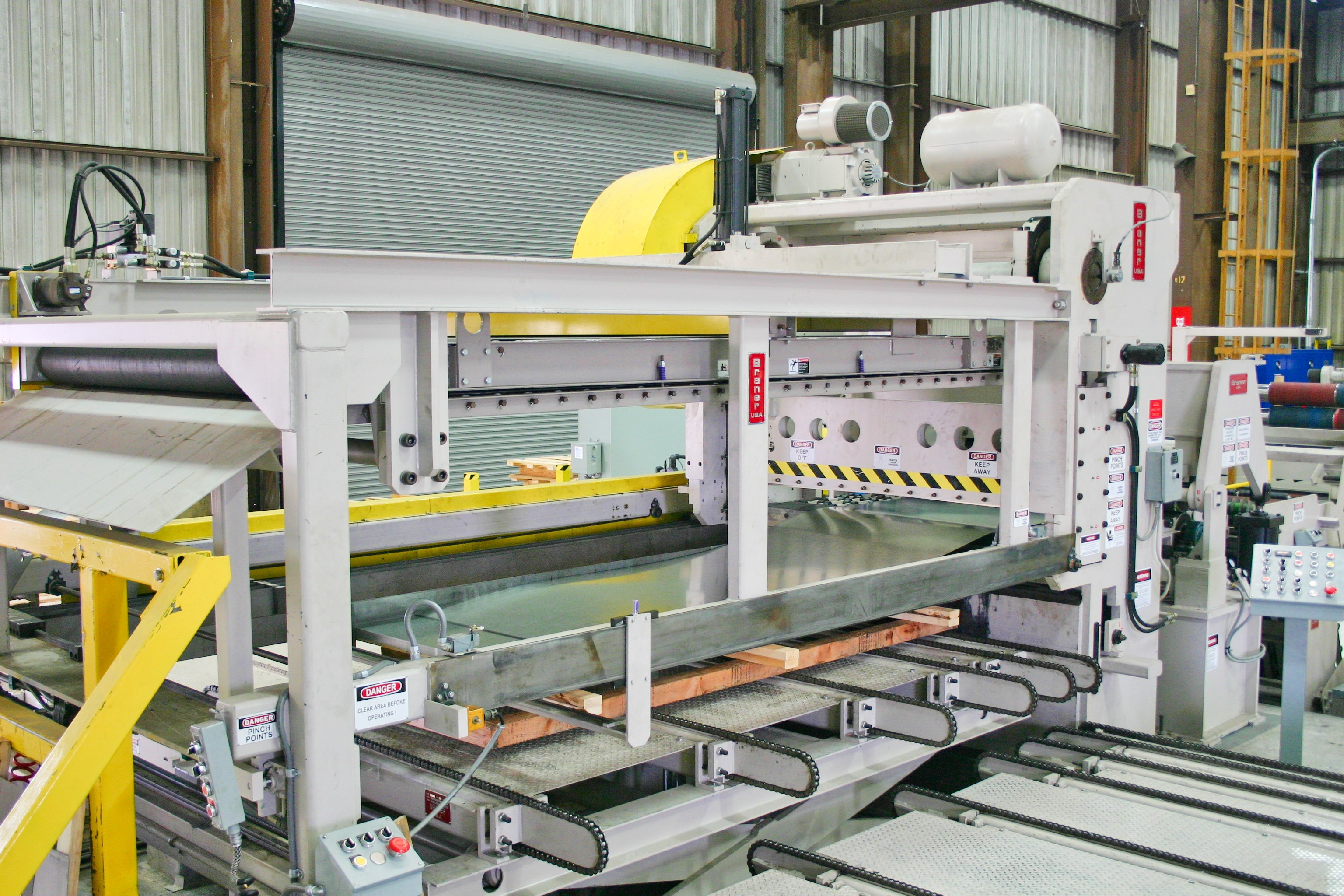

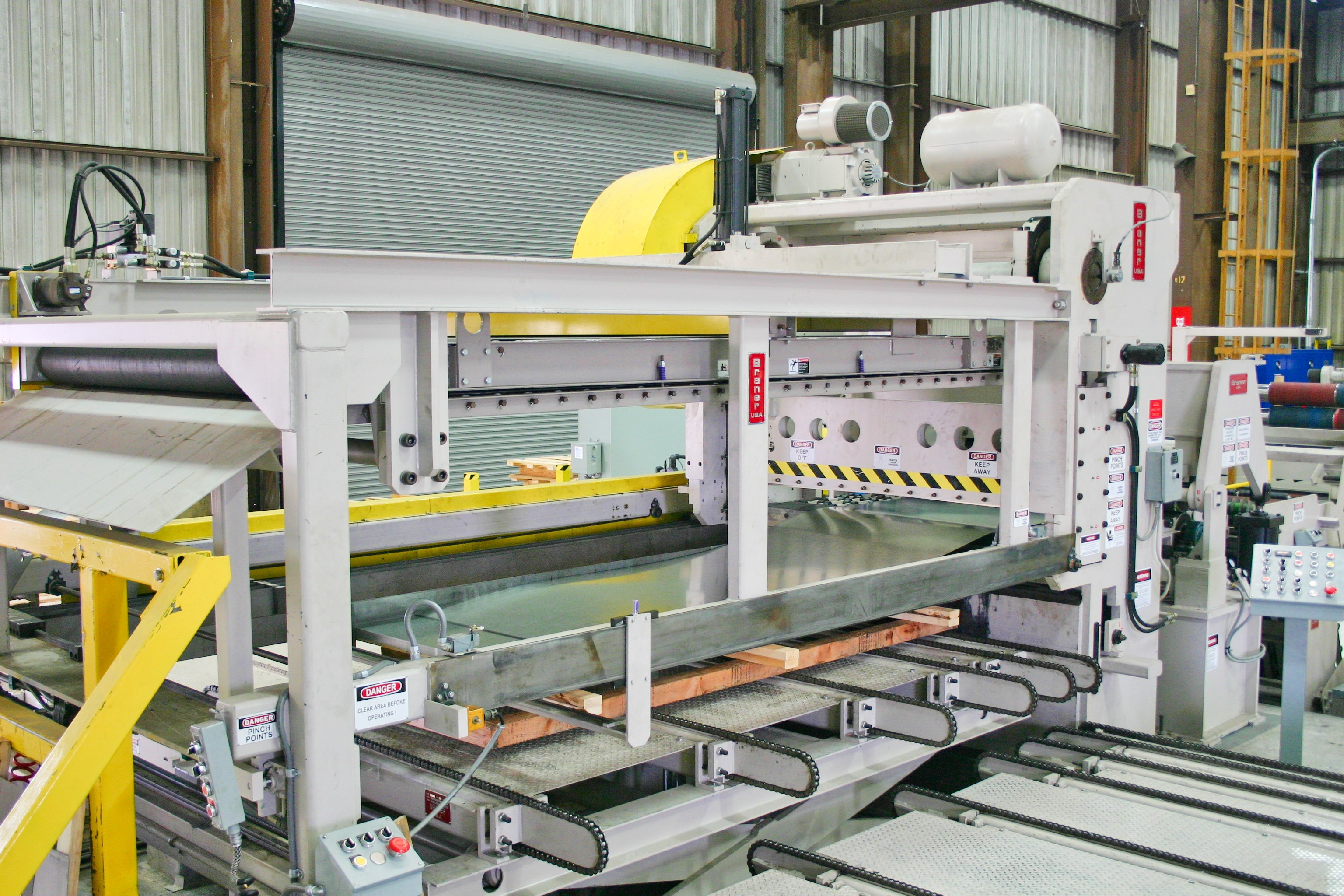

PRECISION LEVELING AND MULTI-BLANKING

Our Braner Multi-Blanking Line is a 60,000# x 72” x 250FPM Automotive Class-1 precision line which blanks in thickness from 0.015” to 0.135”. This is a high-speed close-tolerance line capable of converting bare and coated carbon flat rolled products into panel-flat sheets and precision blanks at a rate of up to 100 cycles per minute. It utilizes a 9 Flight x 5 Hi Cassette Leveler and an inline Slitting Turret Head. Its Hi-Cyclical rate Electronic AC Servo Feed system, combined with its programmable air stacker, allow us to produce the flattest most scratch-free precision tolerance blanks in the region.

TWO-SIDE STRIP INSPECTION AND MAPPING

Our processing facility’s slitter is the only one in the region to incorporate a mill-grade inline inspection stand with strobe lights. This allows for full strip surface inspection and coil mapping, ensuring that we will be able to detect and remove all surface defects (sliver, lamination, inclusion, etc.) per the customer’s requirements.

CORRECTIVE PROCESSING & COIL SALVAGING

What happens when steel enters our facility and is not in user-friendly condition? This is an expensive item to generate scrap because of damage from handling and transportation. With our equipment and coil processing experience, we have the ability to correct defects in order to minimize lost product, ultimately saving our customers money.

WAREHOUSING

With our eight (8) overhead bridge cranes fully serving the 100,000 square foot indoor facility, we are able to store and move master coils of up to 40 tons. The cranes also serve above our Indoor and Outdoor Rail Bays for coil car unloading.

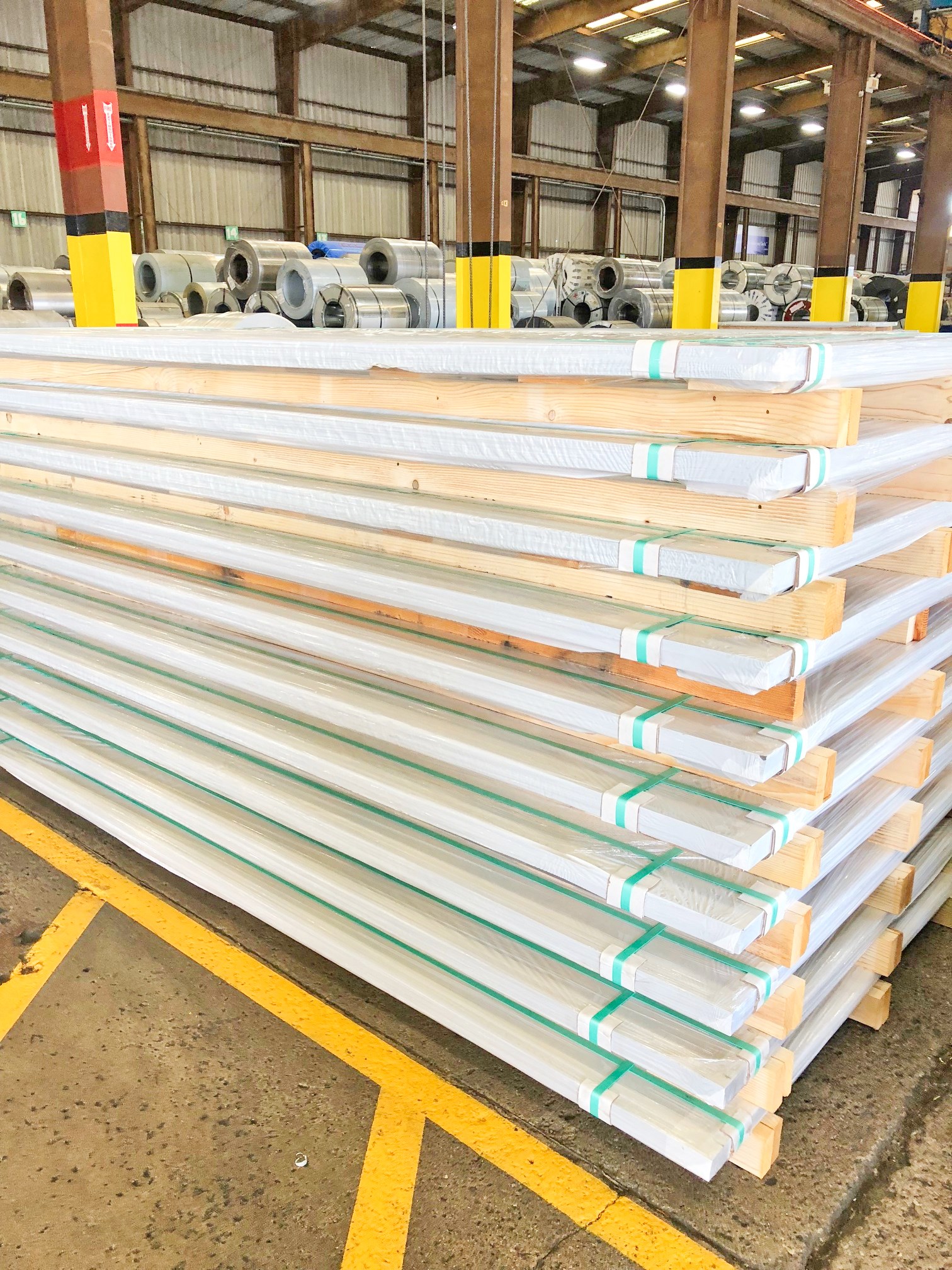

CUSTOM PACKAGING

PTP can produce custom shape and specification skids for both coil and sheet per your requirements. Stretch wrapping, paper wrapping, and VCI bagging are some of the methods used to package material and prevent damage and claims.

RAIL SPUR

In order to maximize efficiency for your logistical and receiving needs, our facility is strategically located on a High Flow Burlington Northern Santa Fe rail spur (Track Number 1153 @ Watson Station). With our rail car spotting vehicle and multiple switches, PTP is capable of both indoor and outdoor rail car unloading of up to several hundred cars per month.

TRUCKING

PTP only utilizes the highest quality transportation equipment in delivering steel to our customers. All of our tractor-trailers and Bobtail trucks are the latest models, specifically equipped with air-ride suspensions in order to ensure safe, damage-free delivery of coil and sheet to any destination. Moreover, our well established working relationships with the many common carrier services allow our customers to have their steel delivered anywhere in the Continental United States with quality and efficiency.

TRANSPORT PROTECTION

We get weather and sometimes that exposure can damage your inventory. We protect your tight tolerances by being the West Coast’s first steel provider to use state of the art flexible coverage on our trailers. It’s just another way that we’re looking out for you!